© 2017-2025 Shangbaotai Machine Technology (Kunshan) Co., Ltd. All rights reserved. Site Map

Buying a noodle making machine for a restaurant is a big decision. You should consider how much noodle production you need daily. Check if your kitchen has enough space for the noodle making machine for restaurant use. Make sure the machine fits within your budget. Look for a noodle making machine for restaurant settings that is durable and built to last. Food safety is crucial, so the machine should meet all hygiene standards. It should be versatile and fit seamlessly into your kitchen workflow. The noodle making machine for restaurant use must be easy to operate and simple to clean. Reliable customer support after purchase is also important. Consider the total cost of ownership, not just the initial price. Restaurants need a noodle making machine for restaurant use that produces consistent noodles every time and operates quickly. More customers are demanding fresh noodles made on-site. Features like automation, customization, and sustainability are key factors. Understanding these points will help you choose the best noodle making machine for your restaurant. Use the following sections as a helpful checklist.

Pick a noodle making machine that matches your restaurant’s daily needs. Make sure it fits in your kitchen space. - Find machines made with safe materials for food. They should be easy to clean and follow safety rules. - Think about your budget. Look at the price and how much it costs to keep the machine working. This helps you get the best deal. - Choose a machine that is simple to use. It should make many kinds of noodles and help your kitchen work faster. - Buy from trusted suppliers. They should give good support, send spare parts fast, and train your staff.

You need a noodle making machine that matches your restaurant’s needs. Small restaurants usually need a machine that makes about 25 kilograms each hour. Medium restaurants often need machines that make between 50 and 100 kilograms per hour. Large or industrial kitchens need much more, sometimes over 150 kilograms every hour. The table below shows how much different businesses might need:

Business Scale | Typical Production Capacity (kg/hr) |

|---|---|

Small | Around 25 |

Medium | Between 50 and 100 |

Large/Industrial | 150 to 200+ |

Picking the right size helps you avoid wasting noodles. It also makes sure you always have enough noodles for your customers.

A noodle making machine for restaurant use should work with the noodles you want to serve. Some machines can make ramen, udon, soba, and pasta if you change the settings. Other machines are made for just one kind of noodle. For example, soba noodles made from buckwheat need a special machine. Ramen machines work best with dough that has less water. The table below shows what features help make different noodles:

Noodle Type | Production Line Features |

|---|---|

Continuous fresh noodle | Makes lots of noodles without stopping |

Small-scale fresh noodle | Good for small shops, can make many kinds of noodles |

Egg noodle | Made for adding eggs, mixes, shapes, cuts, and dries the noodles |

Automatic Chinese noodle | Can make many Chinese noodle shapes, prepares dough, shapes, steams, and dries |

Soba noodle | Works with buckwheat dough, keeps the traditional soba style |

Udon noodle | Kneads, flattens, cuts, and boils dough for udon noodles |

Automatic ramen noodle | Mixes, rolls, shapes, steams, and dries dough for ramen noodles |

Tip: If you want to make many noodle types, pick a machine with settings you can change and features for different noodles.

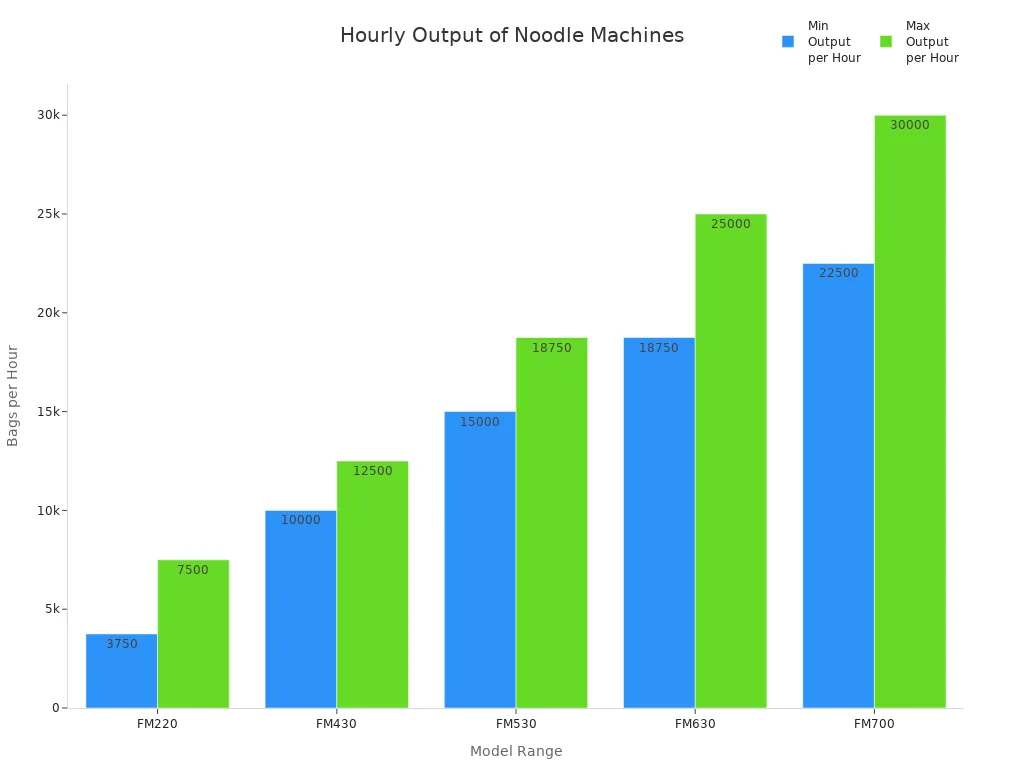

Speed is important when you have lots of customers. Some machines, like the TT-D30A-1, can make 30 kilograms of noodles in one hour. The fastest machines can make up to 350 kilograms every hour. The chart below shows how much different machines can make each hour:

Pick a machine that can keep up when your restaurant is busy. Fast machines help you serve customers quickly and keep lines short.

Check the noodle making machine’s size before buying it. Many commercial machines are small, so they fit in tight spaces. The SIYU Commercial Noodle Pasta Maker is 80 x 40 x 100 centimeters. The HARGSUN AG130-30A is smaller at 62 x 67 x 111 centimeters. Some bigger machines, like the Yamato SHINUCHI series, are 133.5 x 88 x 136.5 centimeters. These machines are made for one person to use and do not need much room. If your restaurant is large, you may need a bigger machine. The Yamato Noodle Production Line needs about 40 square meters. Always measure your kitchen and compare it to the machine’s size.

Machine Model | Dimensions (L x W x H) in cm | Suitable Use |

|---|---|---|

SIYU Commercial Noodle Maker | 80 x 40 x 100 | Restaurants, hotels, food shops |

HARGSUN AG130-30A | 62 x 67 x 111 | Commercial restaurant noodle making |

Good installation keeps your noodle making machine safe and working well. Put the machine on a flat and steady surface. Add the right oil to the reducer so it works smoothly. Ground the machine to stop electrical problems. After moving it, check all bolts and fasteners. Connect the power supply carefully and make sure the motor spins the right way. Check that all parts move easily before starting. Pick a machine that fits your needs now, but also think about the future. Make sure your kitchen has enough space and power for the machine.

Tip: Always use the manufacturer’s guide for installation and get help from a professional if you need it.

A good kitchen layout helps your team work faster and safer. New noodle machines have smart automation and modular designs. These features let you change how you make noodles quickly and keep things running well. Before buying, look at how your kitchen works. Decide if you want to make noodles faster or make the process easier. Try the machine with your recipes to see if it works for you. Work with experts to plan your kitchen’s floor space. Some companies give custom layout tips to help you get the best setup. A smart layout saves time and helps prevent mistakes.

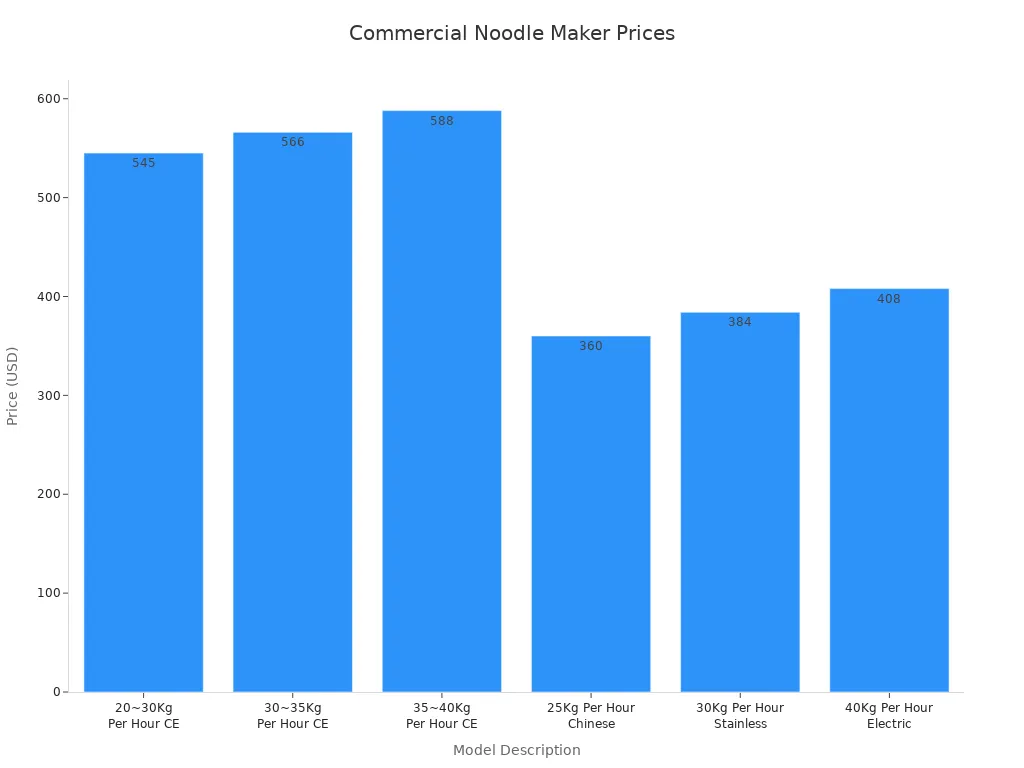

You need to know how much a noodle making machine costs before you buy one. Prices can vary a lot. Some small commercial machines cost between $360 and $588. These machines work well for small restaurants or food shops. Here is a table that shows some common models and their prices:

Model Description | Price (USD) |

|---|---|

20~30Kg Per Hour CE Commercial Electric Noodle Maker | $545 |

30~35Kg Per Hour CE Commercial Electric Noodle Maker | $566 |

35~40Kg Per Hour CE Commercial Electric Noodle Maker | $588 |

25Kg Per Hour Commercial Chinese Noodle Maker | $360 |

30Kg Per Hour Stainless Steel Fresh Noodle Machine | $384 |

40Kg Per Hour Commercial Electric Noodle Maker | $408 |

Some machines cost much more. For example, a basic package from a well-known brand can start at $20,000 to $30,000. Advanced machines with more features can cost $50,000 or more. You can also find second-hand machines for a few thousand dollars. The price depends on the machine’s size, features, and brand.

Tip: Set your budget before you shop. Think about what features you really need.

You should plan for ongoing costs after you buy the machine. Maintenance and repairs usually cost between $500 and $2,000 each year. The cost depends on how often you use the machine, its age, and the vendor’s service charges. Here is a quick look:

Expense Component | Estimated Annual Cost | Notes |

|---|---|---|

Maintenance & Repairs | $500 - $2,000 | Costs vary depending on equipment age, usage intensity, vendor charges, and maintenance schedules. |

Regular check-ups can help you avoid big repair bills. You can save up to 20% on repairs by doing preventative maintenance. Train your staff to handle small fixes and keep spare parts on hand.

A noodle making machine can help your restaurant save money over time. You can make fresh noodles in-house instead of buying them. This can lower your food costs and improve quality. Fast machines help you serve more customers, which can increase your sales. When you choose the right machine, you get better value for your money. Always compare the total cost with the benefits you expect. This helps you make a smart investment for your business.

Note: A good machine pays for itself by saving time, reducing waste, and helping you serve better food.

You need a noodle making machine that works every day. A strong machine will last longer and work better. Good machines use tough materials that do not break easily. Stainless steel is used a lot because it does not rust and is easy to clean. Some machines use cast iron to make them even stronger. These materials help the machine stay good, even if you use it a lot.

Stainless steel: Strong, does not rust, easy to wash

Cast iron: Very tough, lasts a long time

High-quality plastics: Used for some parts that do not touch food

A good machine will save you money on fixing it. You can count on it to make noodles every day.

Food safety starts with using the right materials. Your machine should be made from food-grade stainless steel or safe plastics. These materials stop germs from getting into your noodles and are easy to clean. Stainless steel parts, like mixing tanks and blades, do not rust or get holes. Food-grade plastics, like PP or nylon, are safe and simple to wash. Rubber and silicone seals keep dough inside and can handle heat.

Machines made with food-safe materials last longer and keep your noodles safe. Clean your machine often and use food-safe cleaners to stop germs and keep your kitchen safe.

Aspect | Impact of Food-Grade Materials | Explanation |

|---|---|---|

Safety | Stops germs from spreading | Surfaces that do not rust keep bacteria away |

Longevity | Does not bend or break easily | Strong materials help the machine last longer |

Maintenance | Cleaning is simple | Smooth parts make cleaning fast and easy |

Cost Savings | Saves money over time | Machines can last more than 10 years if you take care of them |

You must check if your noodle making machine follows all food safety and electrical rules. Different places have different rules and marks. In the US, look for UL, CSA, and NSF marks. In Europe, the CE mark is needed. These marks show the machine is safe, easy to clean, and made for food.

Market/Region | Required Certifications and Standards | Material Requirements | Additional Notes |

|---|---|---|---|

Europe (EU) | CE, ISO 9001, ISO 22000/FSSC 22000 | Food-grade stainless steel (304/316) | You need proof and records for these machines |

United States | UL, CSA, NSF, ISO 9001, ISO 22000 | Food-grade stainless steel, plastics | The FDA rules also matter |

Asia | ISO 9001, ISO 22000, local standards | Food-grade stainless steel, plastics | Must follow local food safety rules |

Always ask your supplier to show you proof of these marks. This keeps your business and your customers safe.

You want a noodle making machine that can make many noodle types. Some machines only make one kind. Others let you make lots of different noodles. This helps you give your customers more choices. It also keeps your menu fun and new. The table below shows how some machines are different:

Machine Model | Versatility Highlights |

|---|---|

Yamato Richmen Ramen | Makes all ramen types, gyoza skins, and handles different dough textures. |

Richmen Gold 2 + Silky Mixer | Produces ramen, wok, lo mein, pasta, and reverse-cut noodles; supports menu variety and dough quality. |

Shinuchi Udon | Specializes in udon noodles with soft, chewy texture. |

Bandotaro Soba | Designed for authentic buckwheat soba noodles. |

If you want to add more noodles to your menu, try the Richmen Gold 2 with the Silky Mixer. This machine lets you make ramen, lo mein, pasta, and more. You can please many customers and keep your kitchen ready for anything.

A good noodle making machine should be simple to use. Anyone in the kitchen can learn to use it. You do not need to be an expert. Many machines have features that help your team work faster and make fewer mistakes.

Easy controls let you change noodle thickness and length.

Smart panels have a button to stop the machine fast if needed.

Machines are quiet, so your kitchen is not too loud.

Automatic cutting and mixing save time and help keep everyone safe.

Training and recipe guides help new workers learn quickly.

Feature | Description |

|---|---|

Intelligent Control Panel | Easy settings for thickness, kneading, and cutting. |

Thickness Adjustment | Handwheel for quick, precise changes. |

Low Noise Operation | Quiet running improves focus and teamwork. |

High Output | Makes up to 200 kg per hour for busy times. |

These features help you spend less on training and labor. You can keep your noodles tasting great, even if your staff changes.

Cleaning used to take a long time. Before, you had to take out the rolls and clean them for hours. Now, most machines can be cleaned in about 10 minutes. You just wipe the rolls with citric acid. You do not need to take the machine apart. This saves you time and helps you serve customers faster.

Tip: Clean your machine after every use to keep it safe and working well. Quick cleaning means you can make more noodles and have less waiting time.

When picking a noodle making machine for restaurant use, check the supplier’s reputation first. Good suppliers are trusted because they sell quality machines and give clear details. Many customers say they work with these suppliers for a long time. They like the steady quality and fair prices. Reviews often talk about machines that look nice and clean. People also mention friendly staff and easy buying steps. Find suppliers who believe in “Quality first, Honesty as base.” This means they want you to do well and hope to work with you for years.

Tip: Read what other customers say and talk to restaurant owners you know. The best suppliers get lots of good reviews for their service and reliable machines.

After-sales service is very important for your happiness. You need a supplier who helps you after you buy the machine. Many restaurant owners like getting help from skilled engineers who can visit and fix things fast. Quick and clear support lets you fix problems before they hurt your business. The best suppliers train your staff, share recipes, and help with ingredients. You can call, email, or use apps like WhatsApp and WeChat to reach them. Some companies give a 12-month warranty with free parts and keep helping even after the warranty ends.

After-Sales Service Features | Why It Matters |

|---|---|

On-site engineer visits | Less waiting when things break |

Remote troubleshooting | Fixes problems quickly |

Staff training and recipes | Makes it easy for your team |

Multilingual support | Helps you talk to support easily |

Warranty and ongoing support | Protects your money and machine |

You need to get spare parts fast when something breaks. Top suppliers in China and other places keep many parts ready, like motors, rollers, cutters, and extruders. Many give free parts during the warranty and send them quickly. Some suppliers can even make special parts just for you. Customers say they get parts fast and at good prices. A strong support team means your noodle making machine for restaurant keeps working with little wait.

Suppliers have spare parts like slitters, rollers, and motors.

Many give a one-year warranty with free parts.

Reviews say delivery is quick and service is good.

Some suppliers make special parts and keep high standards.

Note: Always ask if spare parts are easy to get before you buy. This helps you avoid long waits and keeps your kitchen working.

Choosing the right noodle making machine for restaurant use means looking at every detail. You should check size, budget, production needs, and supplier support. A smart choice helps your restaurant grow and keeps customers happy. Use the checklist below to guide your decision:

Match machine size to your space and needs.

Compare prices, features, and materials.

Test machines for noodle quality and ease of use.

Talk with suppliers and ask about support and spare parts.

Take your time to compare options and ask questions. Careful planning leads to long-term success.

You should clean your noodle making machine after every use. This keeps your noodles safe and your machine working well. Quick cleaning also helps prevent dough from sticking and makes the next batch easier to prepare.

Many commercial noodle machines can make gluten-free noodles. You need to use the right dough recipe and check if the machine supports different flours. Always ask the supplier for advice on gluten-free options.

First, turn off the power. Check for loose parts or blockages. If you cannot fix it, contact your supplier’s support team. Many suppliers offer remote help or send an engineer to your restaurant.

Most machines last 10 years or more with regular care. Stainless steel parts and good maintenance help your machine stay strong. Always follow the cleaning and service schedule in the manual.

You do not need special training. Most machines have simple controls and guides. Many suppliers offer free training for your staff. This helps everyone use the machine safely and make great noodles.