© 2017-2025 Shangbaotai Machine Technology (Kunshan) Co., Ltd. All rights reserved. Site Map

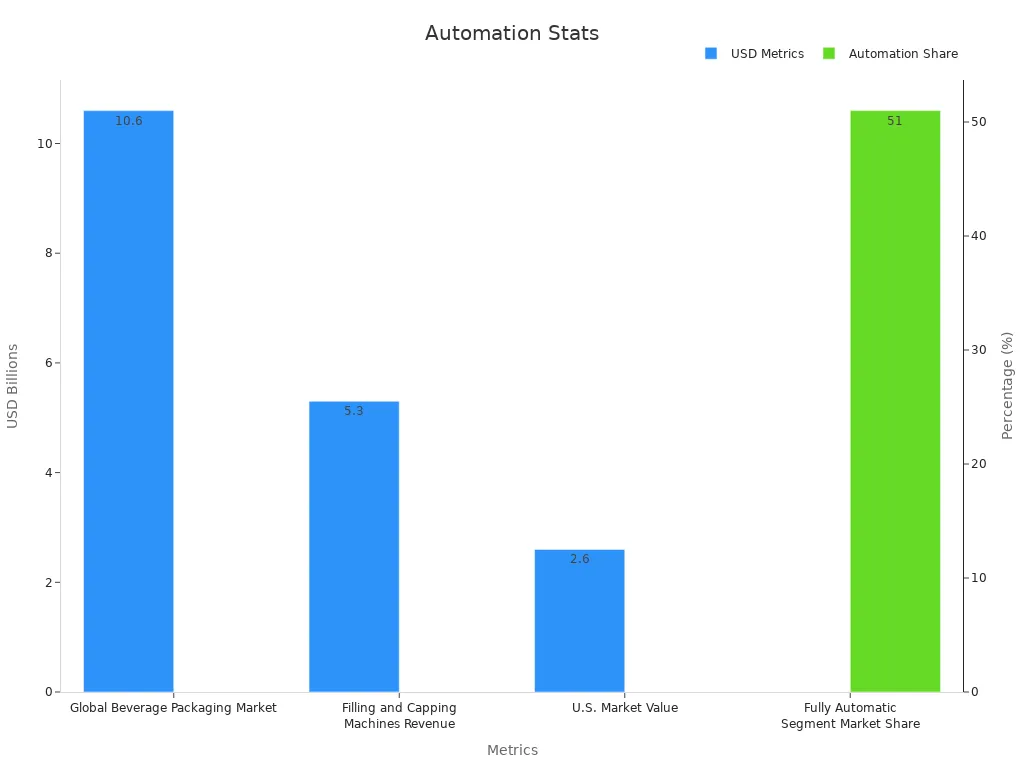

Beverage packaging machines fill, seal, and label drinks with high speed and precision. Automation drives these machines, reducing human error and boosting output. The global market for beverage packaging reached USD 10.6 billion in 2024, with fully automatic systems making up 51% of the market.

Integration plays a vital role, as modern systems combine materials, sensors, and smart features to keep drinks safe and fresh. A beverage packaging machine now often includes technology for tracking, recycling, and real-time monitoring, meeting both industry and consumer needs.

Beverage packaging machines automate filling, sealing, labeling, and packing to boost speed and ensure consistent quality.

Advanced sensors and smart technology help reduce waste, prevent errors, and maintain hygiene throughout the packaging process.

Integrated systems combine multiple steps into one line, increasing efficiency and lowering labor costs for beverage producers.

Choosing the right machine depends on product type, production volume, and maintenance needs to match business goals.

Automation improves safety, cuts costs, and supports sustainability while helping companies grow and meet market demands.

Modern beverage packaging machines perform several integrated functions that transform raw containers into ready-to-ship products. These machines combine filling, sealing, capping, labeling, and overwrapping in a seamless production line. This integration boosts efficiency, reduces manual labor, and ensures consistent product quality. Industry case studies and product descriptions from leading manufacturers show that these machines handle a wide range of package types, including bottles, cans, pouches, and bags. The ability to combine multiple steps into one automated process allows beverage producers to meet high demand while maintaining strict quality standards.

The filling stage is the heart of any beverage packaging machine. During this step, the machine dispenses the correct amount of liquid into each container. Advanced systems use sensors and precision nozzles to ensure every bottle or can receives the same volume. This accuracy prevents waste and keeps product quality high. Manufacturers track several key performance metrics to monitor and improve the filling process:

Key Performance Metric | Description |

|---|---|

Production line throughput | Measures the quantity of products produced in a given time, indicating production speed. |

Defect or rejection rate | Percentage of products failing quality standards, including issues like incorrect filling. |

Downtime | Time when machines are idle due to failures or maintenance, affecting operational uptime. |

Production line efficiency | Ratio of actual production to theoretical maximum, reflecting overall line performance. |

Operator performance | Number of units processed per operator, useful for identifying bottlenecks or training needs. |

Energy consumption per unit | Amount of energy used per product, important for cost and sustainability assessments. |

Machine vision systems now help detect defects in real time, reducing downtime and improving overall performance. By automating the filling process, beverage packaging machines help companies achieve high throughput and consistent results.

After filling, the machine moves each container to the sealing and capping station. This step locks in freshness and prevents leaks. Servo-driven systems place caps with high precision, reducing the risk of misalignment. Digital torque control allows operators to set the exact force needed for each cap, which helps prevent leaks and ensures a tight seal. Advanced cap feeding mechanisms keep the line moving smoothly, while integrated quality control systems check every cap for proper placement and closure.

Precise cap placement is ensured by servo-driven systems that reduce misalignment risks.

Digital torque control allows exact torque adjustments via HMI, preventing leaks and ensuring secure sealing.

Advanced cap feeding mechanisms minimize jams and maintain continuous production flow.

Integrated quality control systems verify cap placement and closure, rejecting defective bottles.

High throughput capabilities range from 20 to 180 bottles per minute, supporting consistent sealing speeds.

Quick changeovers (under 20 minutes) reduce downtime and maintain production continuity.

Servo-driven orientation systems ensure accurate bottle and cap positioning.

Industry 4.0 readiness enables remote monitoring and performance analysis to sustain consistent operation.

Machine reliability and advanced error detection contribute to minimizing production interruptions.

Versatile handling of various cap types and container materials supports flexible, consistent packaging.

Reliable sealing machines maintain steady temperature and pressure, which reduces the need for frequent adjustments. High-grade stainless steel materials improve durability and hygiene. Real-time data tracking and traceability systems monitor sealing counts and rejection rates, helping operators spot and fix problems quickly. These features support consistent, high-quality packaging and reduce the risk of downtime.

Labeling gives each beverage its identity and ensures compliance with regulations. Beverage packaging machines use rotary labelers and inline systems to apply labels quickly and accurately. These machines use sensors and precision technology to place labels in the correct position every time. Rotary labelers reduce downtime and minimize errors, which leads to less label waste and higher production efficiency.

Rotary labelers reduce downtime and minimize labeling errors, leading to less label waste and higher production efficiency.

Customizable labeling options allow handling of different product lines and shapes, supporting continuous, uninterrupted operation.

Seamless integration with existing machinery enhances production flow and reduces maintenance interruptions.

Features supporting eco-friendly materials align with sustainability goals without compromising efficiency.

High precision and speed make rotary labelers ideal for optimizing production lines while ensuring consistent, accurate labeling.

Advanced inline labeling machines adapt to various container sizes and shapes, enabling quick changeovers and continuous production. Consistent label placement preserves brand image and builds customer trust. Automation in labeling reduces human error and operational costs, allowing beverage companies to reinvest in other areas of their business.

The final steps in the beverage packaging process involve overwrapping and packing. Overwrapping machines wrap groups of bottles or cans in protective film or paper, which helps keep products clean and secure during transport. Packing machines then place these wrapped groups into boxes or trays for shipping.

Statistical data shows that the market for overwrapping machines reached $1.92 billion in 2024 and continues to grow. This growth reflects the demand for automated solutions that increase throughput, reduce labor costs, and improve packaging consistency. Modern overwrapping machines use IoT and AI for real-time monitoring and predictive maintenance, which helps reduce downtime and operational disruptions. The shift from manual to automatic machines allows beverage producers to achieve high-volume, continuous production with minimal human intervention. These advancements lead to faster, more precise packing and lower risk of human error.

Note: By combining all these functions—filling, sealing, capping, labeling, and overwrapping—into a single, integrated production line, beverage packaging machines deliver unmatched efficiency and reliability. This seamless operation supports high-speed production and consistent quality, helping beverage companies stay competitive in a fast-moving market.

Modern beverage packaging machines rely on several essential components to deliver efficient, high-quality results. Each part plays a unique role in the packaging process, and together, they ensure uniform fill levels, secure sealing, and smooth product flow.

Pressure regulators control the flow and pressure of liquids and gases within the machine. They help maintain consistent filling speeds and prevent overflows or underfills. By keeping pressure stable, these regulators protect sensitive beverages and support accurate filling. Operators can adjust settings to match the needs of different drinks, such as carbonated sodas or still water. This flexibility helps maintain product quality and reduces waste.

Fill nozzles dispense the beverage into each container with precision. Manufacturers design these nozzles to deliver the right amount of liquid every time. Advanced nozzle designs, like those from Lechler, offer non-clogging features and stable spray angles. Flow meter filling machines use these nozzles to achieve high accuracy and fast speeds. The right nozzle selection improves operational efficiency, reduces waste, and supports automation. Nozzles also help conserve water and lower costs by operating at lower pressures.

Fill nozzles ensure:

Consistent and accurate filling

Minimal product waste

Fast production speeds

Easy cleaning and maintenance

Conveyors move bottles, cans, or pouches through each stage of the packaging process. Smart conveyor systems use sensors and AI to monitor performance and predict maintenance needs. These systems reduce manual labor, speed up production, and improve consistency. Robotics integration allows conveyors to adapt to different product sizes and shapes. Hygiene-focused designs with stainless steel construction make cleaning easy and prevent contamination. Integrated sensors and cameras inspect products in real time, ensuring only quality items continue down the line.

Key benefits of conveyors:

Automated product movement

Reduced contamination risk

Flexible handling of various container types

Real-time quality control

Capping systems seal each container after filling. They use servo-driven motors and digital torque controls to place caps securely and prevent leaks. These systems handle different cap types and materials, supporting a wide range of beverages. Reliable capping protects freshness and prevents contamination. Operators can monitor and adjust capping performance using control panels and sensors, which helps maintain high quality and minimize downtime.

Note: The performance of each component is measured using Overall Equipment Effectiveness (OEE). OEE combines availability, performance, and quality to give a complete picture of machine efficiency. This data-driven approach helps operators identify areas for improvement and maintain optimal operation of the beverage packaging machine.

Modern beverage packaging machine processes follow a precise, step-by-step sequence. Automation and smart technology drive each stage, ensuring speed, accuracy, and product safety. Below is a detailed look at each step in the typical process.

The process begins with infeed and preparation. Operators load bulk containers, such as bottles or cans, onto the infeed conveyor. Bottle unscramblers orient the containers, making sure each one faces the correct direction. This step prepares containers for smooth movement through the line.

Sanitizing the containers is essential. Rinsing and washing machines use ionized air or purified water to remove dust and microbes. This step protects the beverage from contamination. Pallet builders may transfer completed pallets from storage to the conveyor infeed area. Electronic sensors detect the presence of pallets and control their movement, advancing them stepwise into the next zone. This organized flow sets the stage for efficient, hygienic filling.

Automated filling is the heart of the beverage packaging machine process. The machine dispenses the exact amount of liquid into each container. High-speed filling machines can process up to 600 bottles per minute. Precision in liquid dispensing often reaches within ±0.5% accuracy, reducing waste and ensuring every container meets quality standards.

Feature | Manual Filling | Semi-Automatic | Fully Automatic |

|---|---|---|---|

Production Speed | 15 pouches/min | 60 pouches/min | 120 pouches/min |

Accuracy (ml deviation) | ±5 ml | ±2 ml | ±1 ml |

Labor Cost Reduction | 0% | 40% | 70% |

Compliance | Basic | Partial | Full (FDA/CE) |

Smart conveyor systems and IoT technologies monitor the filling process in real time. These systems help minimize downtime and maintain consistent product quality. Regular calibration and high-speed fillers can reduce cycle times by up to 30%. Fully automatic filling machines can lower labor costs by up to 70%. Many beverage packaging machines use form-fill-seal technology, which forms the container, fills it, and seals it in one continuous process. Specialized machines, such as water packing machines, handle specific beverage types and packaging formats.

After filling, the containers move to the sealing and capping station. Selecting compatible caps and bottles ensures a proper fit and seal. Operators perform regular maintenance and calibration of capping equipment to keep performance high. Automated systems use robotics and vision inspection tools to monitor the process in real time.

Thermal imaging-based inspection checks the integrity of induction seals through the caps. This technology detects issues such as under- or overheating, damaged lips, and misaligned or missing foil. The system operates at full production speed, providing 100% inspection coverage. Real-time data helps operators optimize the process and reduce recalls or waste. Predictive maintenance uses key performance indicators like seal integrity rates and rejection rates to keep the line running smoothly.

Labeling and coding give each beverage its identity and ensure traceability. Automated labelers apply labels quickly and accurately, adapting to different container shapes and sizes. Sensors and cameras verify label placement and readability. Inline coding systems print batch numbers, expiration dates, and barcodes directly onto the packaging.

IoT-enabled solutions select the correct packaging format and monitor the labeling process. Automated traceability ensures product consistency and safety throughout production and transit. AI and robotics control the application of labels and codes, eliminating errors and supporting compliance with industry regulations.

Quality control is present at every stage of the beverage packaging machine process. Sensors and cameras detect defects immediately, ensuring only high-quality products move forward. Real-time monitoring collects production data, helping operators optimize processes and reduce waste.

Metric | Description |

|---|---|

Overall Equipment Effectiveness (OEE) | Measures machine utilization combining availability, performance, and quality. Indicates how effectively equipment is used. |

First Pass Yield (FPY) | Percentage of products passing inspection without rework, indicating process reliability and quality. |

Throughput | Number of units produced in a given time, reflecting productivity and bottlenecks. |

Yield | Amount of saleable product from raw materials, indicating process control and waste reduction. |

Downtime | Time lost due to unplanned stoppages, directly affecting profitability and productivity. |

Scrap Rate | Amount of waste generated during production, indicating quality or process issues. |

Maintenance Metrics (MTTR & MTBF) | Mean Time To Repair and Mean Time Between Failure, showing machine health and maintenance effectiveness. |

Cycle Time | Time to produce one unit, impacting efficiency and speed to market. |

Customer Complaints or Returns | Tracks quality from the customer perspective, highlighting real-world product performance. |

On-Time In Full (OTIF) Delivery Rate | Measures reliability in fulfilling orders on time and in full, reflecting supply chain performance. |

Operators use these metrics to balance speed and quality. Intelligent automation and strict quality control processes help maintain high throughput without sacrificing product standards. Automated storage and retrieval systems improve post-manufacturing handling and scalability, ensuring that finished products reach customers safely and on time.

Tip: Automation in beverage packaging machine processes delivers faster processing times, consistent output, and round-the-clock production. Real-time monitoring and predictive maintenance keep lines running efficiently, while data-driven insights help optimize every step.

Beverage packaging machines transform production speed in the industry. Companies see a 7.9% rise in packaging output per unit of labor, and multifactor productivity increases by 6.8%. Over half of packagers report higher productivity after automation. For example, Syntegon’s capsule-filling machine can double output to 360,000 capsules per hour. AI-powered systems and IoT sensors help predict issues and reduce downtime, keeping lines running smoothly.

Benefit Type | Impact Example |

|---|---|

Labor Productivity Increase | 7.9% more output per worker |

Multifactor Productivity | 6.8% overall efficiency gain |

Automation & IoT | Less downtime, faster troubleshooting |

Technological Advancement | Output doubled with advanced filling machines |

Automated packaging lines deliver reliable results every time.

Machines fill containers with precise amounts, reducing the need for extra quality checks.

Automation lowers contamination risks, which is vital for food and beverage safety.

Increased speed does not lower quality; it often improves it.

Gentle handling preserves the product’s integrity.

Consistent operation eliminates errors common in manual work, building customer trust.

Modern beverage packaging machines use robots and specialized conveyors to keep products safe.

Robots reduce contamination by limiting human contact, which is a main source of germs.

Food-grade robots use safe lubricants and stainless steel parts for easy cleaning.

Clean-in-place systems allow machines to sanitize themselves without being taken apart.

Real-time monitoring with AI and X-ray scanners finds impurities quickly.

Conveyor belts use antimicrobial materials and special coatings to stop bacteria and make cleaning easier.

Note: These features help protect beverages during transportation and storage, reducing spoilage and costly recalls.

Companies save money with automated packaging.

Transportation costs for plastic containers drop by 73% and by 50% for metal containers due to volume reduction.

Automation increases packaging speed by up to 50%, reduces errors, and lowers material costs.

Quality control costs go down, and less labor is needed as production grows.

Durable machines mean lower maintenance costs over time.

PepsiCo, for example, cut operational costs by 20% and increased production volume by 25% after installing new bottling machines.

Selecting the right beverage packaging machine requires careful consideration of several factors. Companies must match machine features with their product type, production volume, and maintenance needs to ensure efficient and reliable operation.

The type of beverage and its packaging shape play a major role in machine selection. Market studies segment machines by product type, packaging type, automation level, and application. Companies should consider the following:

Product characteristics such as size, shape, weight, and fragility influence machine compatibility.

Packaging types include flexible, rigid, and semi-rigid containers.

Machines must handle recyclable or biodegradable materials if sustainability is a priority.

Automation levels range from manual to fully automatic, each suited to different needs.

Applications extend beyond beverages to processed foods, bakery, and health foods.

Tip: Conduct a thorough product analysis and request machine trials to ensure the equipment aligns with specific beverage requirements.

Production volume determines the level of automation and investment needed. Machines must match the required speed and capacity. The following table outlines typical machine types and their suitability:

Machine Type | Investment Range (USD) | Suitable Production Volume |

|---|---|---|

Manual | 5,000 - 15,000 | Less than 1,000 units/day |

Semi-Automatic | 15,000 - 50,000 | 1,000 - 5,000 units/day |

Fully Automatic | 50,000 - 200,000+ | More than 5,000 units/day |

Other important considerations include:

Bottle shape and thickness affect machine choice.

Adjustable process parameters help accommodate different package weights.

A compact machine footprint optimizes plant space.

Higher automation reduces labor costs and increases flexibility.

Proper maintenance ensures long-term performance and reduces downtime. Companies should establish routine schedules and follow manufacturer guidelines. Key maintenance practices include:

Regular cleaning to prevent debris buildup.

Lubrication of moving parts to reduce friction.

Frequent inspection of motors, sensors, and electrical systems.

Calibration to maintain accurate packaging.

Keeping detailed records of inspections and repairs.

Timely replacement of worn parts.

Employee training on safe operation and maintenance tasks.

Using maintenance management software to track schedules and equipment history.

Predictive maintenance technologies help forecast needs and minimize unexpected breakdowns.

A well-maintained beverage packaging machine supports consistent quality and efficient production.

Beverage packaging machines help companies streamline production and drive business growth. These machines automate repetitive tasks, reduce downtime, and optimize labor. They deliver consistent product quality, which improves brand reputation and customer loyalty. Companies benefit from:

Higher operational efficiency and lower production costs

Reliable packaging that meets safety and regulatory standards

Scalability for new product launches and market expansion

Support for sustainability through recyclable packaging

Companies should review their product needs, production goals, and maintenance plans before choosing a beverage packaging machine. Automation continues to shape the industry, offering speed, flexibility, and new opportunities for success.

Beverage packaging machines process water, soft drinks, juices, dairy products, energy drinks, and alcoholic beverages. Manufacturers design machines to accommodate various container shapes and sizes for each product type.

Manufacturers use stainless steel parts, automated cleaning systems, and sealed environments. These features prevent contamination and support food safety standards. Operators monitor hygiene with sensors and regular inspections.

Many modern machines feature adjustable settings and quick-change parts. Operators can switch between bottle sizes or shapes with minimal downtime. This flexibility supports diverse product lines.

Operators should follow a regular maintenance schedule based on manufacturer guidelines. Routine checks, cleaning, and part replacements help prevent breakdowns and ensure consistent performance.

Beverage packaging machines use emergency stop buttons, safety guards, and automatic shut-off sensors. These features protect operators and prevent accidents during operation.